Successful product development goes beyond design.

With our custom-build experience, practical backgrounds and the capacity afforded by our purpose-built design and development centre, we can support you beyond the design phase.

Strong manufacturing links and technical partners combined with our procurement and supply chain management expertise, enable us to deliver development, build and commissioning services to help you realise your design into the finished product.

Our range of flexible turnkey production and build solutions deliver quality, well-built and fully tested products that will fulfil the aspirations of your customer.

Procurement and Supply Chain Management

With nearly 20 years of Engineering and Design capability, CADceptual Design have developed and maintained a strong and reliable supply chain. All of our suppliers are ISO, Mil Spec and List x accredited and provide both quality parts and service alongside competitive pricing.

UK manufacturing has increased steadily since 2016 and as a result we have seen in increase in demand for our ‘Build to Print Kit’ service.

Perhaps you don’t have a procurement team or they’re overloaded? Maybe the project timescale is challenging your internal systems and you need to bypass your usual procurement process in order to achieve your customer commitments. If this is the case you can outsource you’re procurement activity to us.

All you need to do is provide a Bill of Materials (BOM) and data pack and our team will manage the sourcing, quoting and delivery on your behalf. It may be that you require machined parts, sheet metal or welded fabrications, PCBs or connectors. You may have a requirement for bought out items ranging from specialist mirrors to drive systems, nothing is out of scope for us, and we’ll even supply the nuts and bolts!

Customers benefit from competitive pricing through our preferred supplier network and our fixed margin covers the full procurement and supply chain management service. We take all the strain and pain out of the buying process for you with a single purchase order and our team will manage the supply chain right through to delivery of parts in ‘one drop’. Customers who have already taken advantage of our service, report that they have seen improved delivery times with some seeing an overall reduction in the cost of getting parts from ‘BOM to Build’ on to the shop floor.

Contact us to find out more detail about how this service could support your business.

Build services

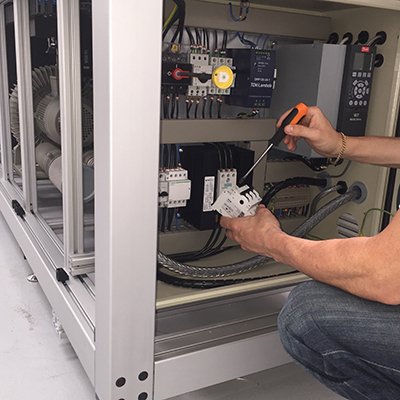

Our flexible approach and sound understanding of multiple engineering disciplines enables us to undertake a variety of build projects.

In our design and development centre, we can build, integrate, test and commission the following systems:

- Electro mechanical

- Electronic, PCB & PLC

- Control & Instrumentation

- Automation

- Pneumatic & Hydraulic

Our on-site design department provides an immediate and closed-loop process, ensuring build issues are quickly rectified and any modifications or improvements are fed back into the design under our revision control processes. With these proven processes and controls in place, we can deliver an efficient and robust build service.

Build Support Equipment

The design process will shape a product, aligning it with the relevant manufacturing and production methods, assembly techniques and skill sets available.

Additional efficiencies can be gained by utilising a range of build support equipment, such as:

- Jig & fixtures

- Production tooling

- Test rigs & endurance rig

- Electrical test & break out boxes

This equipment can streamline the production and build process by:

- Providing a high degree of accuracy

- Improving work holding

- Reduce setting and process time and reducing skill levels and associated labour costs

At CADceptual Design, we can help you achieve uniform repeatable quality reduce inspection costs, reduce scrap, improve productivity and cut unit cost whilst maintaining process-related safety.

Low Volume Production (LVP)

The very nature of our design and development service has structured our business to manage, build and deliver individual build projects. These processes and techniques can be easily scaled-up to provide a Low Volume Production service.

The LVP service can support your business where:

- You have no production capability or spare capacity

- Your production facility struggles with low volume, unique or multiple configuration products

- You require short-term production whilst you bring volume production on-line

- You require small batches of product for qualification testing, field trials and marketing

To see our expertise in action, visit our Case Studies page, or contact us to discuss how we can help deliver your next project.