At the heart of even the simplest product, you'll find a great design idea, the right technology and sound engineering.

Our product portfolio and breadth of industry exposure has provided us with a wealth of transferrable skills, knowledge and competency, allowing us to fully understand the design and technical engineering aspects of any undertaking.

Our team of multi-disciplined engineers combine years of practical experience and methodology with the confidence to innovate and bring concepts to life and successful products to market.

Whatever your industry or market sector, we can support you and your business with our proven design and technical engineering solutions.

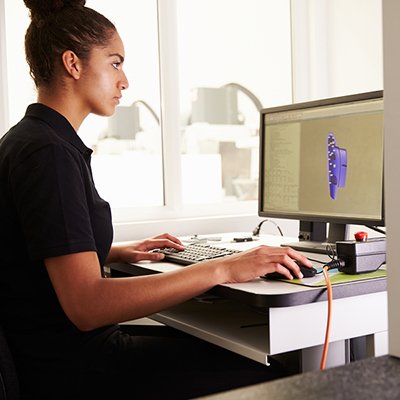

Mechanical Design and Engineering

At the core of any successful product is sound mechanical design and engineering, ensuring it not only performs the required task, but performs it well.

Drawing on our background in special purpose machinery, we have the competency in complex mechanical systems, mechanisms, automation, pneumatics and hydraulic systems to provide innovative solutions to demanding engineering challenges.

With our extensive knowledge of manufacturing processes, materials and ‘design for manufacture’ techniques, we deliver enhanced solutions that are well-designed, perfectly executed and fulfil your brief.

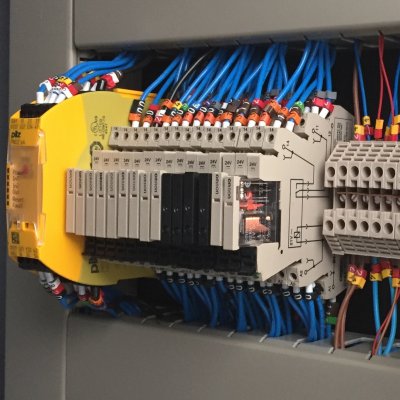

Electrical and Electronics Design

From complex machinery to high-volume consumer goods, an effective product needs to deliver on every level. To satisfy increasing functionality, performance and size demands, it’s vital to complement sound mechanics with robust electrical and electronic design and engineering.

Our electrical experience enables us to design/define hardware, instrumentation and control systems, while managing feedback loops and safety circuits effectively. This is matched by our experience in electronics, which enables us to control the software, programmes and user interfaces.

We add value to these disciplines with full procurement, manufacture, build and wiring services, enabling us to deliver:

- Electrical panel and enclosure build

- Full product/machine wiring

- Break Out, test boxes and cable assemblies, including IPC-610-Class A

- HMI and GUI screens design and programming

- PLC programming

- PCB design, layout and manufacture including MIL Spec and List-X

Design for Manufacture (DFM) and Assembly (DFA)

Adopting sound DFM and DFA principles is paramount. Both factors must be considered early in the design cycle, to shape the product and ensure it fulfils the aspirations of both the customer and your business.

CADceptual Design’s specialist team boasts many years of experience, covering everything from complex machinery to high-volume consumer products. Drawing on this industry-wide exposure, we are conversant in a range of DFM techniques such as conventional/CNC machining, sheet metal/welded fabrication, casting and compression/injection moulding.

Our DFA experience such as snap fits, orientation features, adhesives and ultrasonic welding enables us to reduce the number of components, product complexity and assembly time, eliminating faults and improving cost-efficiencies.

With our bespoke tooling, jigs and fixture design-and-build service, we add value, further optimising the assembly process, increasing yields and boosting your profits.

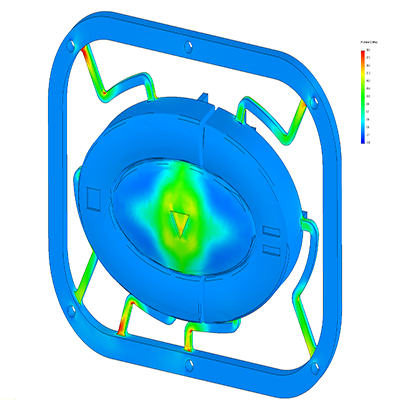

Analysis and Testing

Close analysis throughout the product design cycle can help identify, isolate and address issues. This allows you to optimise your product’s form, function and efficiency, significantly reducing risk.

Through effective analysis and testing, our team can help you validate your design, providing reassurance that it will deliver the functional requirements and withstand the operational and environmental conditions, ahead of the costly downstream manufacturing investment.

Our main Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) tools enable us to carry out:

- Linear Static

- Non-Linear

- Advanced Dynamic

- Thermal & Cooling

- Flow

Additional validation can be carried out by physical testing, plus we can design and build a range of dynamic, endurance and load rigs, and functional test boxes as required. We can also manage EMC, RF, environmental and safety testing through our test-house partnerships.

Effective analysis and testing is key to successful product development and will feed into the next phase of product prototyping and optimisation.